Preparing to Fly the Challenger 850

Published: 24 June 2021

New flight simulator helps ARM Aerial Facility pilots prepare for formal certification training

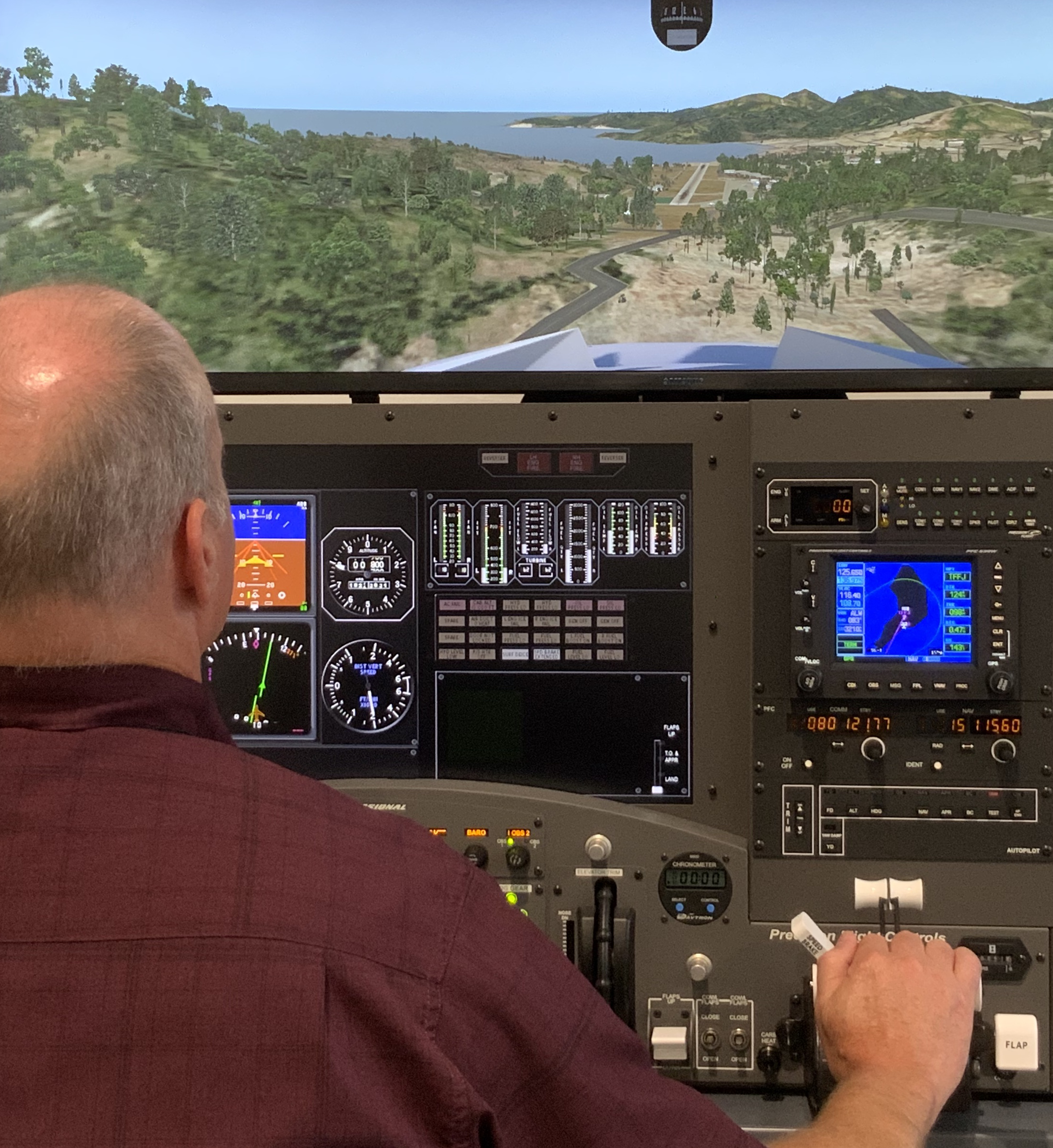

The controls are sensitive and precise. Slight pressure on a left foot pedal changes direction, and an overcorrection with the right could steer you off the runway. Speed increases with the intensity of the turbines, and with a gentle pull on the yoke, you’re airborne in a digital version of a twin-engine business jet.

Nudging the yoke to keep it even with the horizon, the flight progresses high above the virtual wheat fields and vineyards of southeastern Washington state. All this, without leaving the friendly confines of the Atmospheric Radiation Measurement (ARM) Aerial Facility (AAF) hangar at the Tri-Cities Airport in Pasco, Washington.

From takeoff to landing, the tabletop simulation replicates flight and instrument procedures, but it’s no video game, says AAF Manager Beat Schmid. “This simulator has the basic controls and the instrumentation required to provide our pilots refresher training on instrument procedures before attending flight training for ARM’s Bombardier Challenger 850 jet.”

ARM expects to take delivery of the new jet in 2022, once again providing ARM users the opportunity to gather aerial atmospheric data above ARM observatories and for field campaigns around the world.

‘Knocking Off the Rust’

According to Schmid, who also serves as a manager at Pacific Northwest National Laboratory (PNNL), the flight simulator provides self-guided refresher training for experienced pilots and better prepares them for formal training and the aircraft certification process.

Since the December 2018 retirement of ARM’s previous research aircraft, a vintage Grumman Gulfstream-159 (G-1) turboprop, “none of (the pilots) have flown anything significant or have worked through instrument procedures,” explains Tim McLain, who joined PNNL in late summer 2020 to oversee AAF flight operations and training. He is also an AAF pilot.

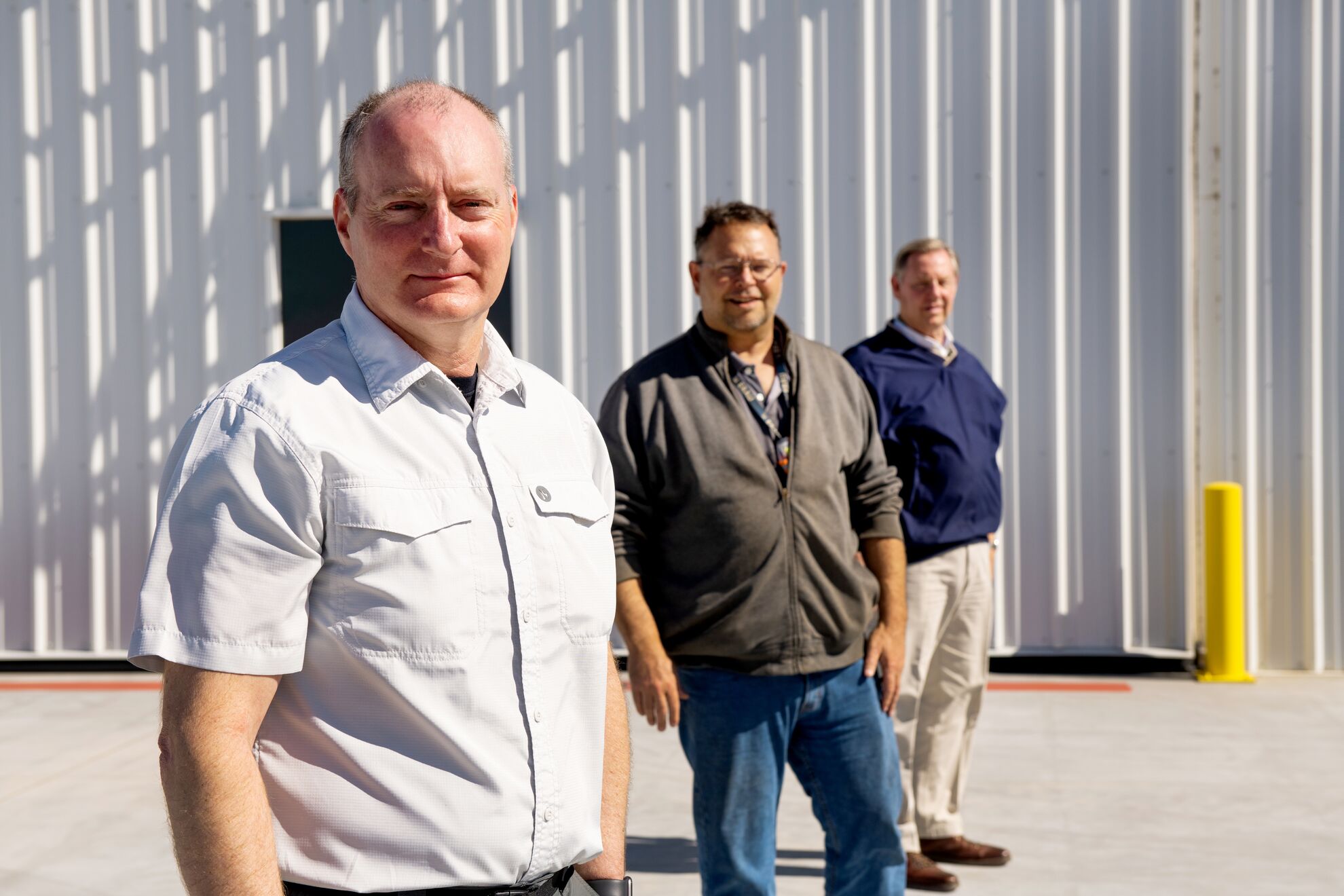

The other AAF pilots are Mike Hubbell and Jonathan Ray.

“This simulator is Federal Aviation Administration (FAA)-certified so that once we get current in the new aircraft, we can maintain that currency,” says McLain.

(“Currency” in a specific airplane means that a pilot has met the FAA’s requirements for taking on the role of pilot in command during a flight.)

“For now, we’re using the flight simulator to brush up on our instrument procedures and knocking off the rust on our cross-checks as we’re scanning different instruments,” continues McLain.

Adds Ray: “AAF flights are not typical, so it’s critical to focus on training and operational safety.

“We are going to fly the Challenger 850 unlike any airline. We will fly different profiles, at different speeds, and at different altitudes. We may fly at 300 feet over water at just 200 knots and later spiral up to 30,000 feet or more to slice the atmosphere. We must know the aircraft and its handling characteristics inside and out.”

Getting Ready to Fly

The flight simulator, says Schmid, is just a tool—albeit a critical tool—to ultimately get the AAF’s trio of pilots FAA-certified to fly the new airplane under sometimes extraordinary conditions and be ready to fulfill the science missions of ARM users.

For more than 20 years, Hubbell has flown atmospheric research campaigns. According to Schmid, Hubbell’s vast experience with planning and executing these flights will be critical to the successful implementation of the Challenger 850.

Since 2014, Ray has flown for the AAF as a pilot and aviation safety officer, participating in multiple field campaigns along the way. His PNNL role is that of worker safety and health representative. No matter the job, this veteran pilot speaks passionately about safety and training.

“Safety is the most important aspect of our work,” says Ray, noting that each of the AAF pilots has flown large aircraft and has an airline transport pilot rating, the highest certification issued by the FAA.

None, however, has yet operated or is certified to fly the Challenger 850.

“The simulator helps us become more fluent in the flight profiles and instrument procedures so that we will absorb more during our formal training. After our formal training, we’ll know the systems and be both trained and certified to fly the Challenger 850.”

Jonathan Ray, ARM Aerial Facility pilot and aviation safety officer

That, notes Ray, is why the AAF is in a transition period to the new aircraft. The transition is typically achieved by working with a company that provides formal ground and aviation training—a necessary step to achieve FAA certifications.

Before this step, in addition to sharpening their skills with the flight simulator, AAF pilots are becoming familiar with the cockpit through static training, running checklist exercises for cockpit familiarity, and focusing on systems training.

“The simulator helps us become more fluent in the flight profiles and instrument procedures so that we will absorb more during our formal training,” says Ray. “After our formal training, we’ll know the systems and be both trained and certified to fly the Challenger 850.”

After receiving their FAA certification in the Challenger 850, the pilots will begin logging flight time with an experienced captain. “By the time we’re finished,” says Ray, “each of us will have 100 to 120 hours in both the left and the right seats (as pilot in command and co-pilot).”

It’s not just the pilots who will receive training. Science aircrew training includes AAF staff at PNNL.

“It’s important that our scientists learn the scientific payload systems and how to operate all those systems and how they interface with the aircraft systems,” says McLain. “It’s quite an extensive process, but it is designed to keep us safe.”

Flying the World Without Leaving Home

Whether it’s the Azores in the eastern North Atlantic, ARM’s Southern Great Plains observatory in Oklahoma, or the skies above the Amazon canopy in South America, the flight simulator—with its sophisticated software—is designed to acquaint pilots with airports around the world, runway configurations, regional topography, and flight conditions, says McLain.

With a push of a few buttons, the simulator changes from the hot, sunny runway at the Tri-Cities Airport to a snow-covered landscape in New Jersey. “The simulator can change the time of day and the flight conditions—sun, fog, snow and ice, high winds, turbulence, and more,” says McLain.

“Ultimately,” concludes McLain, “the simulator is preparing us today for further training later. In the future, it will be an indispensable part of mission planning and safety.”

Keep up with the Atmospheric Observer

Updates on ARM news, events, and opportunities delivered to your inbox

ARM User Profile

ARM welcomes users from all institutions and nations. A free ARM user account is needed to access ARM data.